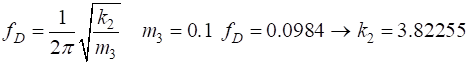

|

DOING

PHYSICS WITH MATLAB COUPLED

OSCILLATORS PART 2: TWO COUPLED OSCILLATORS MATLAB SCRIPTS oscC002.m Script to model the motion of a pair of coupled oscillators connected

between three springs. Calls the function simpson1d.m (need to download this file). All the variables are changed within the Script. Some of the

input variable that you can change include: mass, spring constant, time

steps, time span, damping constant, driving force. The results of the

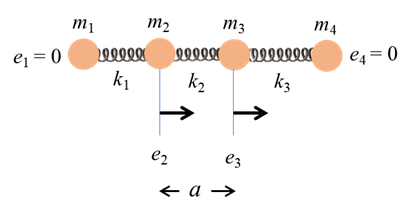

modelling are displayed in Figure Windows and in the Command Window. INTRODUCTION We will consider a one-dimensional chain of 4 particles

each of mass mc (c = 1,

2, 3, 4). The particles are coupled by massless

springs each with force constant ks

(s = 1, 2, 3). Let ec

be the

displacement from the equilibrium position of the cth particle along the X axis. The

equilibrium separation distance between particles is a.

The ends of the

left- and right-hand springs are assumed fixed

Fig. 1

Longitudinal oscillations of 2 particles connected by massless

springs. The end particles are always in their equilibrium positions. We can investigate many important aspects of vibrating systems for the [1D] motion two particles oscillating between three springs using the Script oscC002.m ·

Harmonic

motion ·

Damped

harmonic motion ·

Forced

harmonic motion ·

Modes

of Vibration ·

Natural

frequency of vibration and resonance ·

Fourier

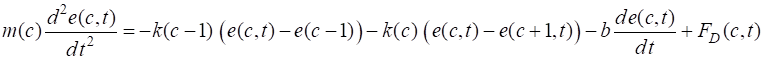

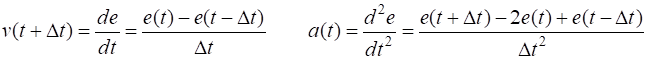

Transform The elastic restoring force (1) We will assume that a damping force (2) where We approximate the velocity and acceleration using a finite difference scheme

(3)

We can use equation 2 and equations 3 to calculate the displacement e

from equilibrium at each successive time step The code used for the implementation of the finite difference method is KS = dt^2.*k; Kb =

b*dt;

KD = dt^2; for nt = 1 : Nt-2 for c = 2 :

N-1 e(c,nt+2) = 2*e(c,nt+1) - e(c,nt)...

-(KS(c-1)/m(c)) *

(e(c,nt+1) - e(c-1,nt+1)) ...

-(KS(c)/m(c)) *

(e(c,nt+1) - e(c+1,nt+1)) ...

- (Kb/m(c))

* (e(c,nt+1) - e(c,nt)) ...

+ (KD/m(c))

* FD(c,nt+1); end end The displacement at time step nt+2 depends on the displacement at the

two previous time steps. Therefore, to

start the calculations, it is necessary to specify the displacement and

velocity of the particles at the first two-time steps. For example, particle 2 starts with a

displacement of 5 mm and zero velocity e(2,1) =

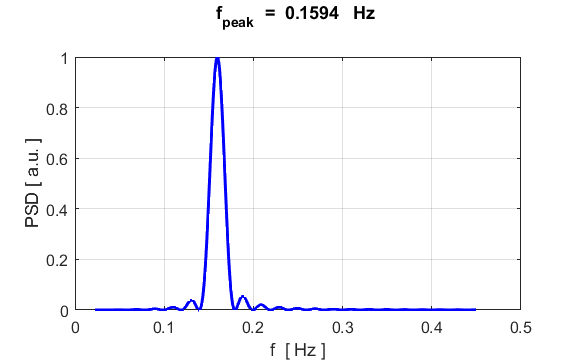

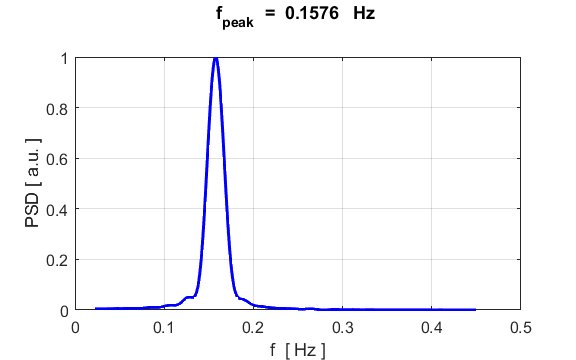

0.005; e(2,2) = 0.005; For a non-zero initial velocity for particle 2, the input is such that e(2,1) The component frequencies of the displacement from equilibrium for

particle 2, can be found from its

Fourier

Transform by direct

integration (not a fast Fourier Transform) % Fourier Transform

fMin = 0.1*f0;

fMax= 2*f0;

Nf = 201;

H = zeros(1,Nf);

f = linspace(fMin,fMax,Nf);

for c = 1:Nf g = e(2,:)

.* exp(1i*2*pi*f(c)*t); H(c) = simpson1d(g,tMin,tMax);

end

PSD = 2.*conj(H).*H;

PSD = PSD./max(PSD);

[xx, yy] = findpeaks(PSD,f,'MinPeakProminence',0.5);

f_peak = yy;

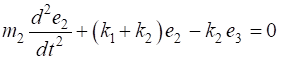

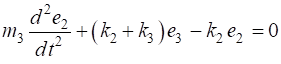

FREE VIBRATIONS: NATURAL MODES For the free motion of the system, the equations of motion for the two

particles are

(4A)

(4B) Assume that the two particles vibrate harmonically with the same

angular frequency

(5)

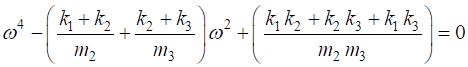

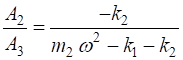

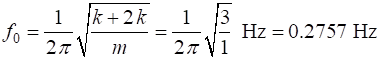

After much algebra, equations 5 gives a solution to the equation of motions (equations 4), provided

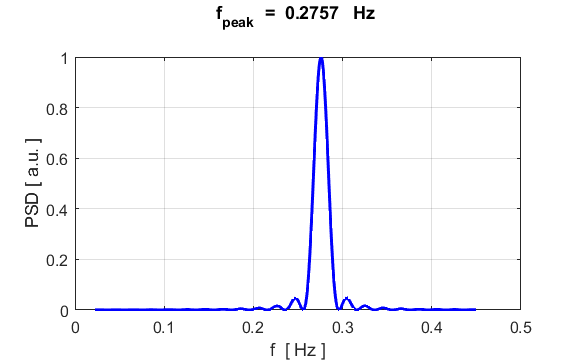

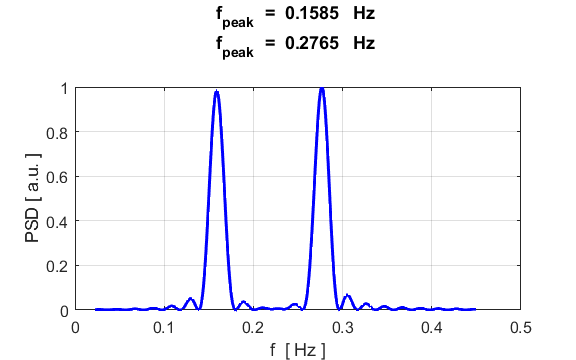

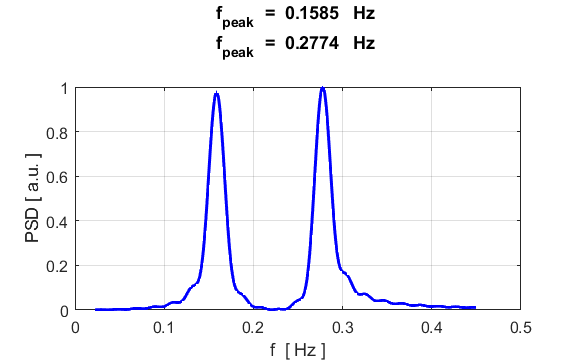

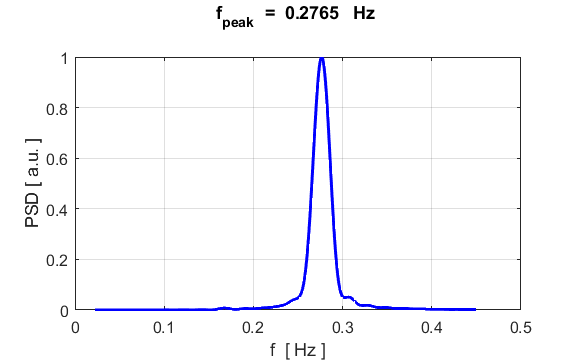

(6) and the amplitudes are given by the ratio (7) Equation 6 is known as the frequency equation and leads to two values for How well do our numerical simulation values compare with the

analytical values? For free motion of the two particles, a summary of the analytical (A)

values and numerical (N) values are displayed in the Command Window. For

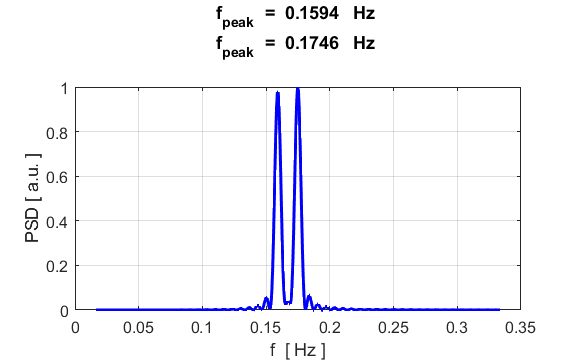

example: % Initial conditions [0.0025 m] e(2,1) = 0.005; e(2,2) = 0.005; e(3,1) = 0; e(3,2) = 0; FREE MOTION: Natural modes of vibration Analytical A f_A = 0.1592

Hz f_A = 0.2757

Hz Numerical N (Fourier

Transform peaks) f_N = 0.1585

Hz f_N =

0.2765 Hz There is an excellent agreement

between the analytical and numerical values. The default values for each mass and

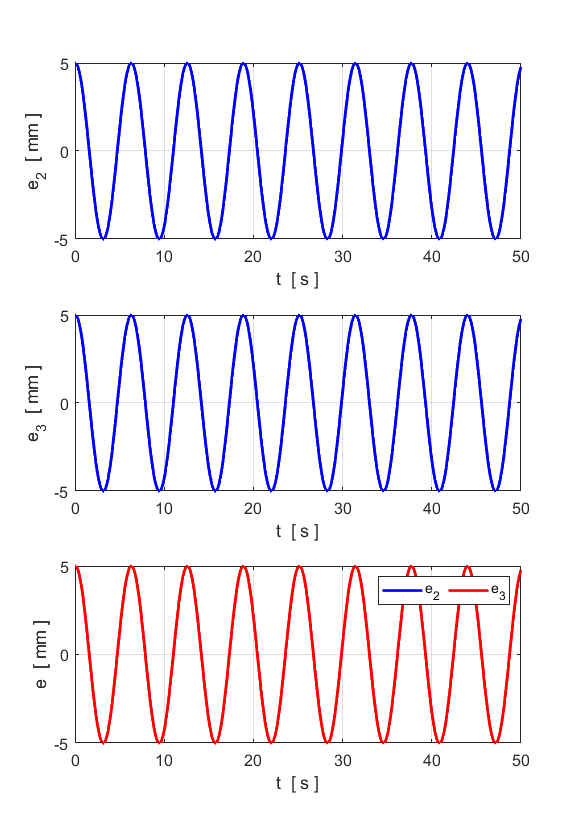

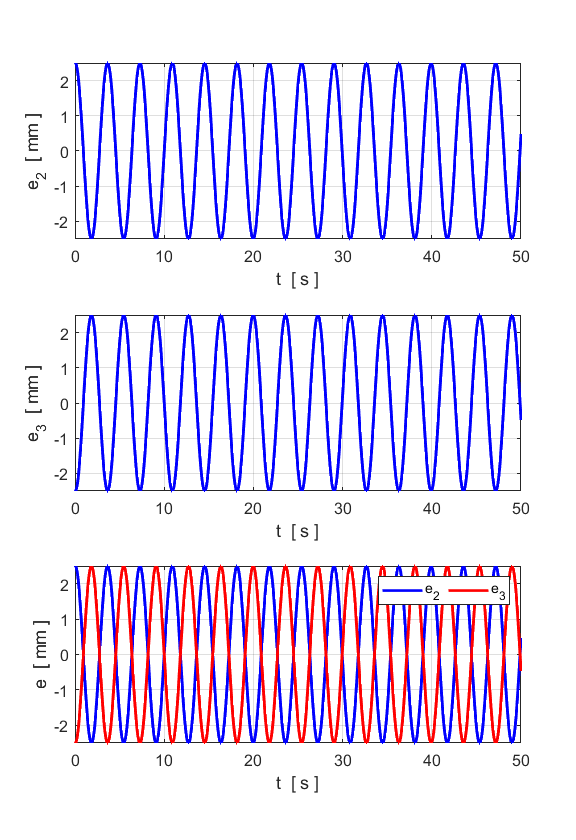

each spring constant are: Simulation #1 SHM % Initial conditions [0.0025 m] e(2,1) = 0.005; e(2,2) =

0.005; e(3,1) = 0.005; e(3,2) = 0.005; The two particles move in the same

direction through the same displacement. The coupling spring is not

compressed or stretched during the motion. Hence, the motion is purely

sinusoidal with the natural frequency

The motion corresponds to two independent single-degree-of-freedom systems.

Simulation #2 SHM % Initial conditions [0.0025 m] e(2,1) = 0.0025; e(2,2) = 0.0025; e(3,1) = -0.0025; e(3,2) = -0.0025; The two particles move in opposite

directions but through the same distance. The two motions are

Thus, there are two natural modes of

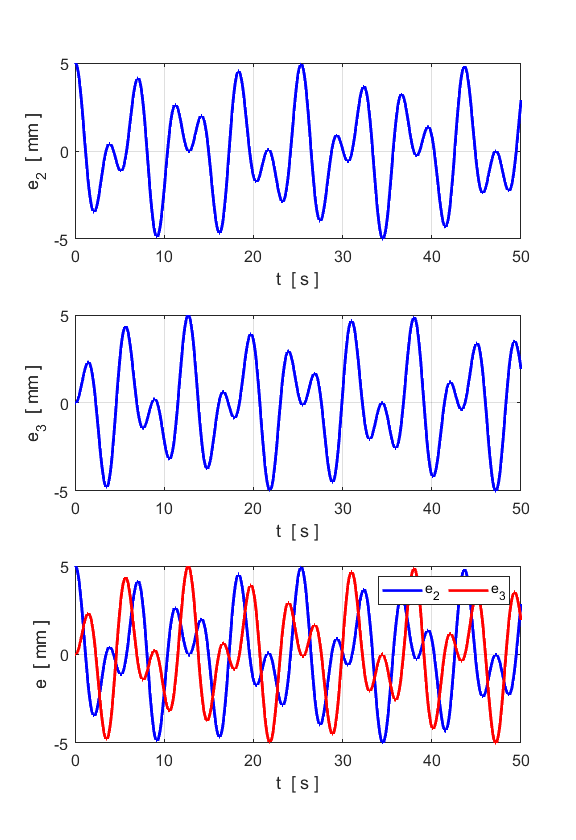

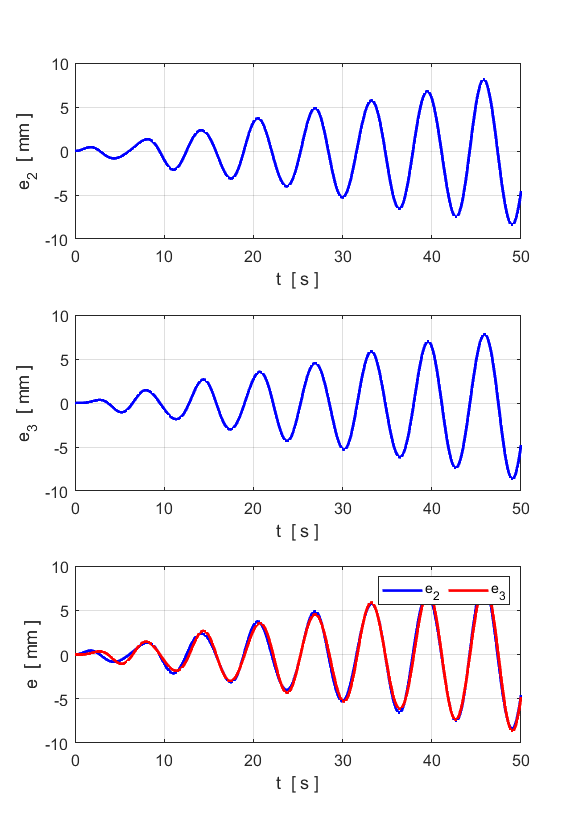

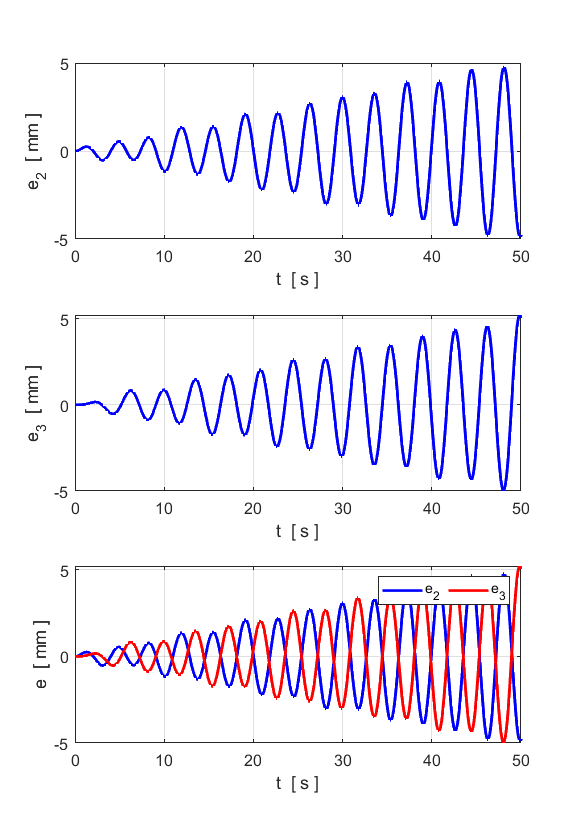

vibration each with its natural frequency as shown in simulations #1 and #2. Simulation #3 Superposition

and Periodic Motion For other initial conditions, the

motion is a superposition of the two sinusoidal natural modes of vibration.

For the initial conditions where the first particle is given a non-zero displacement

while the second particle’s displacement is zero, the first particle

vibrates with large amplitude while the second stands practically still.

After a time, however, the difference in the two frequencies will have

changed the phase between the two vibrations by % Initial conditions [0.0025 m] e(2,1) = 0.005; e(2,2) = 0.005; e(3,1) = 0; e(3,2) = 0;

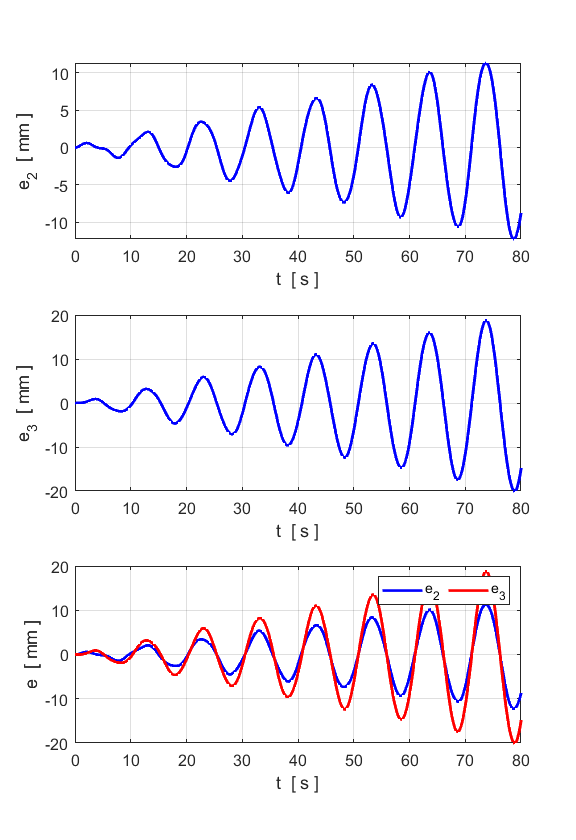

Simulation #4 BEATS When the combined motion of the

particles is not sinusoidal, the motion must be a combination of the two

natural frequencies. When the coupling spring constant k(2) is must less than the spring constants

k(1) and k(3), the two natural frequencies will have values that are close

together and so beats will occur. k(2) =

0.1; % Initial conditions [0.0025 m] e(2,1) = 0.0025; e(2,2) = 0.0025; e(3,1) = 0; e(3,2) = 0;

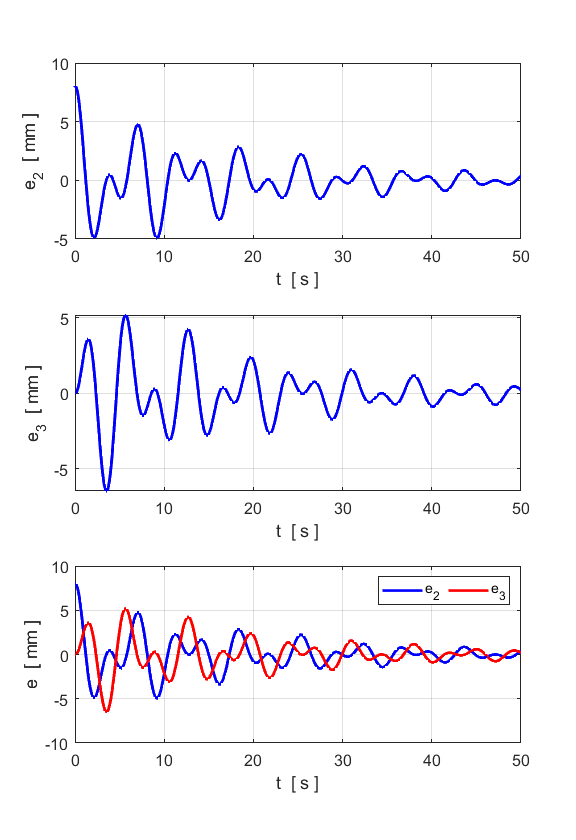

DAMPED MOTION You can change the damping parameter

to study the damping of the coupled oscillators. The following results are

for b = 0.1 and zero

driving force, AD = 0.

Simulation #5 % Initial conditions [0.0025 m] e(2,1) = 0.008; e(2,2) = 0.008; e(3,1) = 0; e(3,2) = 0;

The damping causes the oscillations

to die away. The larger the damping constant b, then the more rapid the decay

in the oscillations. FORCED MOTION and

RESONANCE The default values for each mass and

each spring constant are: We will assume that both particles

start at rest and that the system is not damped (b = 0). % Initial conditions [0.0025 m] e(2,1) = 0; e(2,2) = 0; e(3,1) = 0; e(3,2) = 0; There are two normal modes of

vibration: (1) the particles move in the same direction through the same

distance at a frequency of 0.1592 Hz and (2) the particles move in opposite

directions through the same distance at a frequency of 0.2757 Hz. We can apply a sinusoidal driving

force to particle 2 and study its response of the system to a

sinusoidal driving force % Driving force [N]/Amplitude [0.1

N]/period [1.6T0]/particle number [2] fD0 = 0.2757; AD = 0.0007; FD = zeros(N,Nt); FD(2,:) = AD*cos(2*pi*FD0*t); You can adjust the frequency of the driving force FDO and its

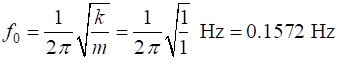

amplitude AD. Simulation #6 Driving frequency

equals normal mode 1 frequency 0.1572 Hz

Simulation #7

Driving frequency equals normal mode 2 frequency 0.2757 Hz

Simulation #8 Driving

frequency not equal to a natural frequency of the system

When the system is driven at one of

its natural frequency, the response is that large amplitudes of oscillation

occur. This phenomenon is called resonance.

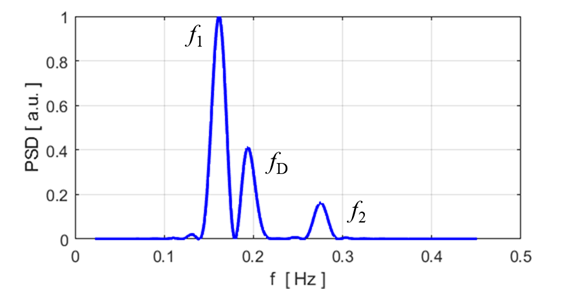

In this simulation, when the system is driven at a frequency that is not

equal to a natural frequency, then the three dominate peaks in the frequency

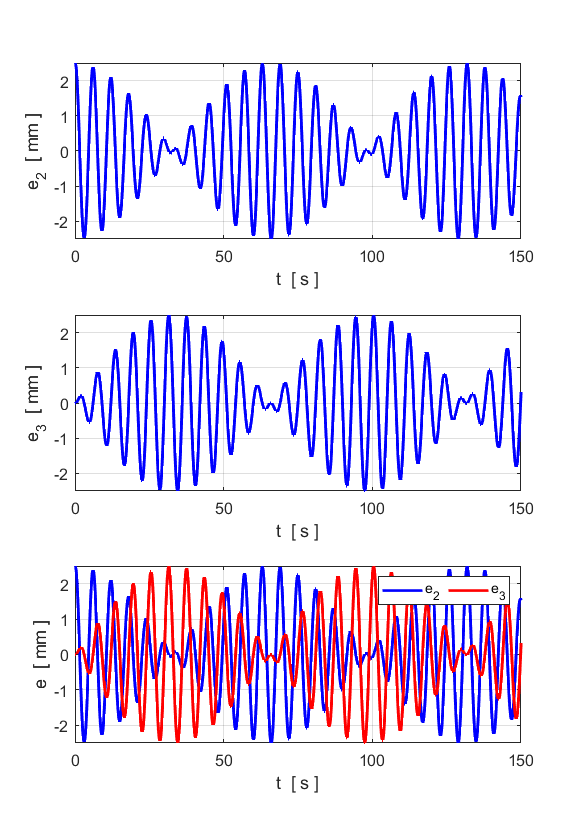

spectrum where close to the natural frequencies and the driving frequency. Simulation #9 The undamped dynamic

vibration absorber A machine or machine part on which a

steady alternating force of constant frequency is acting may take up

obnoxious vibrations, especially when the driving frequency is close to

resonance. On many occasions, it is not practical or even possible to

eliminate the driving force to reduce the unwanted vibrations. You may

consider changing the mass or spring constant to get way from resonance, but

in many cases, this also is impractical. A third possibility is in the

application of a dynamic vibration absorber. Let the machine part be represented

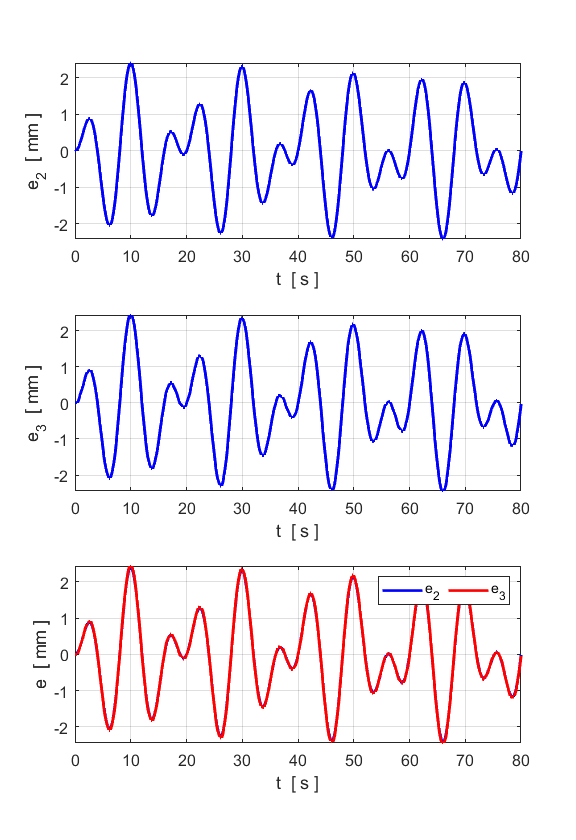

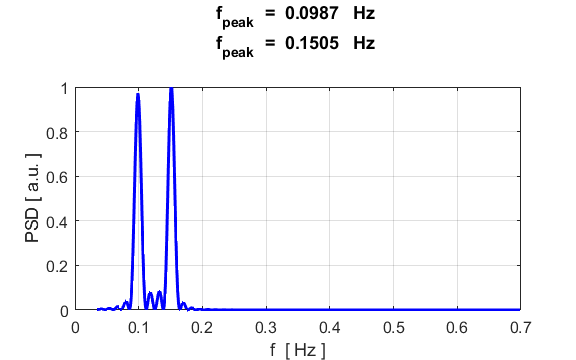

by particle 2 ( Consider the system with the

following specifications: e(2,1) = 0; e(2,2) = 0; e(3,1) = 0; e(3,2) = 0; m(2) = 1; m(3) = 1; k(1) = 1; k(2) = 1; k(3) = 0; AD = 0.0007; fDO =

0.0984;

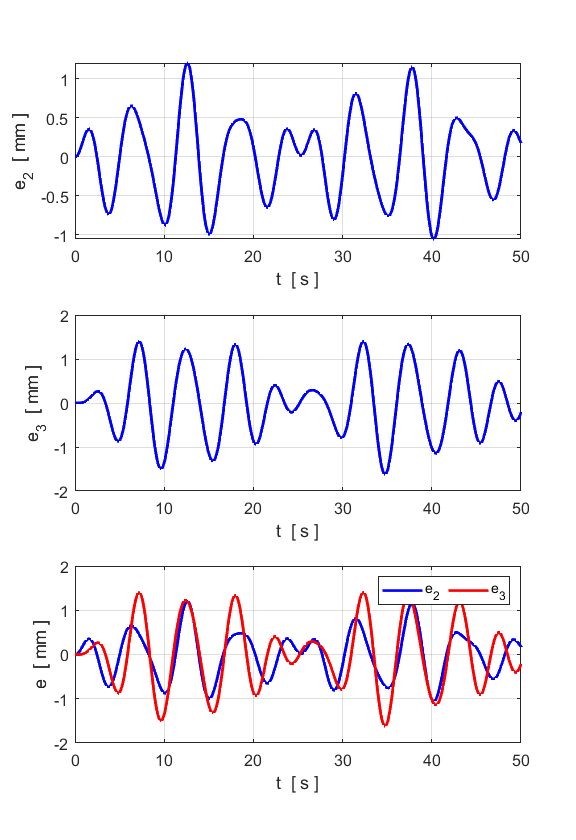

For our machine part, the oscillations

continue to grow in time and the displacement from equilibrium becomes

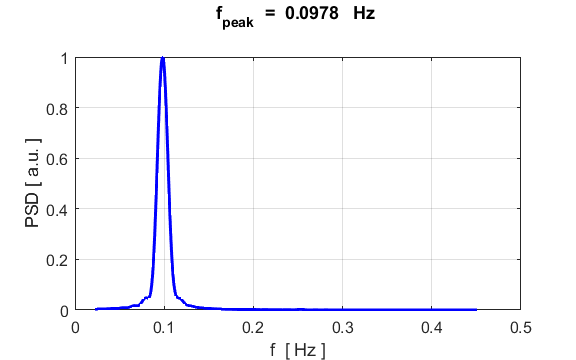

greater than 10 mm. We can set the mass of the absorber

to be

We get an important result. The

oscillations do not continue to grow but reach a maximum steady-state value

of around 2.5 mm. By better selection of the values for |